As bobinas de sacos impressas com tecnologia FFS utilizam impressão reversa, que retém a tinta entre camadas de película protetora. Esse método protege a arte gráfica contra arranhões e umidade durante o manuseio e transporte em armazéns, ajudando a preservar a aparência da marca. Além disso, proporciona cores vibrantes e resistência a arranhões que duram mais tempo do que a impressão em superfície ao longo do ciclo de distribuição.

A percepção do consumidor é influenciada pela forma como a embalagem é apresentada nas prateleiras dos varejistas.

Com a impressão em superfície, sua marca fica exposta na película externa, onde entra em contato com paletes, esteiras transportadoras e outras embalagens. Essa exposição causa desbotamento, arranhões e desgaste durante a distribuição normal.

Para comida para animais de estimação Ou, no caso de marcas de fertilizantes voltadas para segmentos de varejo premium, gráficos danificados comprometem o posicionamento de qualidade que você construiu.

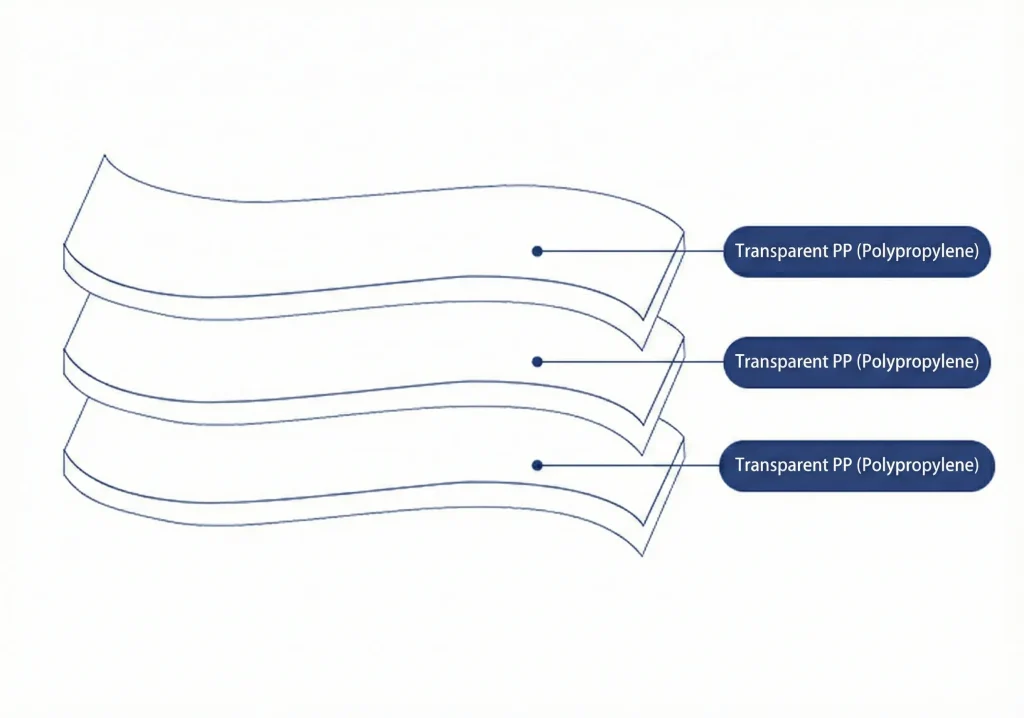

A impressão reversa aplica tinta na superfície interna de uma película transparente e a cobre com uma camada protetora. Os consumidores visualizam sua marca através da película externa transparente que protege a tinta contra danos por contato.

Os ambientes de distribuição revelam diferenças de desempenho entre estes métodos.

| Recurso | Impressão de superfície | Impressão reversa |

| Localização da tinta | Superfície externa visível | Lado interno da película transparente |

| Nível de exposição | Contato direto com abrasão e umidade. | Protegido entre camadas de película |

| Aparência ao longo do tempo | Degrada-se com o manuseio. | Mantém a vivacidade original |

| Durabilidade | Arranhões e desbotamentos | Mantém-se intacto durante a distribuição. |

| Efeito visual | Acabamento padrão | Aparência brilhante com profundidade de cor |

| Uso típico | Embalagem básica, rótulos simples | Produtos de varejo premium |

Como funciona a impressão reversa em sacos de filme FFS

Essa abordagem envolve quatro etapas de produção interligadas.

A equipe de design prepara os gráficos digitalmente e espelha a imagem. O espelhamento garante que o texto e os logotipos sejam lidos corretamente quando visualizados de frente. A arte invertida é então enviada para a impressora com a separação de cores ajustada ao substrato do filme.

As impressoras de rotogravura de alta resolução aplicam tinta na superfície interna de uma película transparente. Este método de impressão proporciona:

Uma segunda camada de material adere à película impressa, selando a tinta entre as camadas. Essa estrutura normalmente combina uma película impressa transparente com tecido de PE ou PP, que confere resistência à sacola para produtos pesados.

O material laminado passa pelo equipamento de ensacamento FFS. A máquina forma os sacos, os enche com o produto e os sela em operação contínua.

O posicionamento de um produto premium exige embalagens que resistam aos desafios de distribuição.

Sacos para fertilizantes ou ração para animais de estimação são empilhados em paletes, movimentados por armazéns, carregados em caminhões e expostos em pontos de venda. Sacos FFS com impressão reversa protegem sua marca contra:

Os seus produtos gráficos ficam idênticos nas prateleiras das lojas tal como ficavam depois de saírem da produção.

A impressão visualizada através de uma película protetora transparente cria uma superfície brilhante que atrai a atenção. A tinta protegida mantém a nitidez das cores, algo que a impressão em superfície perde durante a distribuição. Essa diferença visual reforça o posicionamento premium do seu produto quando comparado a concorrentes com embalagens padrão.

As cores, os logotipos e as informações do produto permanecem nítidos e legíveis. Se os elementos gráficos da embalagem se deteriorarem, os consumidores associam essa queda à qualidade do produto. A impressão protegida preserva a integridade da marca desde a fabricação até a venda.

Utilizamos equipamentos que proporcionam a qualidade gráfica exigida por marcas premium.

O Grupo XIFA opera uma impressora rotogravura de 8 cores que produz imagens de alta resolução em embalagens de filme FFS. A capacidade de oito cores permite designs complexos com correspondência de cores precisa, gradientes suaves e detalhes fotográficos que diferenciam os produtos premium das alternativas comuns.

Nossa equipe de design oferece serviços gratuitos de criação de embalagens. Desenvolvemos elementos gráficos que atendem às necessidades da sua marca:

Nossa equipe entende o desempenho de diferentes tintas em vários substratos de filme. Esse conhecimento ajuda você a evitar problemas de transferência inadequada de designs de serigrafia para a película impressa. Recomendamos combinações de materiais que produzem os efeitos visuais desejados.

Gerenciamos todo o fluxo de trabalho, desde os conceitos iniciais até os rolos impressos prontos para o seu equipamento de ensacamento FFS. O controle de qualidade monitora a consistência da cor em todas as tiragens, garantindo que cada embalagem atenda às suas especificações.

Entre em contato com nossa equipe de design para discutir bobinas FFS impressas em rotogravura para sua marca.

A impressão reversa protege a tinta entre as camadas da película, evitando arranhões e desbotamento durante o manuseio.

A impressão reversa funciona com substratos de filme transparente como BOPP ou PE que permitem visualizar gráficos através da camada externa transparente. O filme deve ser compatível com o processo de laminação que protege a tinta impressa.

A impressora rotogravura de 8 cores do Grupo XIFA é capaz de produzir designs complexos com correspondência de cores precisa, gradientes e qualidade fotográfica. Essa capacidade permite o desenvolvimento de marcas premium que diferenciam os produtos no varejo.