Dans le secteur de la construction actuel, qui évolue à un rythme effréné, l'efficacité et la précision sont aussi importantes que les matériaux eux-mêmes. sac de béton géant, également connu sous le nom de sac jumbo de ciment, sac jumbo en béton, ou sac jumbo pour cimentCette solution d'emballage en vrac innovante simplifie le stockage, le transport et la manutention des matériaux de construction. Ces sacs réduisent les pertes de matériaux, font gagner du temps et améliorent l'organisation des chantiers, ce qui les rend indispensables aux projets de construction modernes.

Dans cet article, nous allons expliquer ce que sacs de béton géants Vous découvrirez ce que sont les outils, comment ils fonctionnent et pourquoi ils sont essentiels dans la construction. Vous apprendrez également leurs principaux avantages et comment emballage géant transforme la manière dont le béton et le ciment sont stockés, transportés et coulés sur les chantiers.

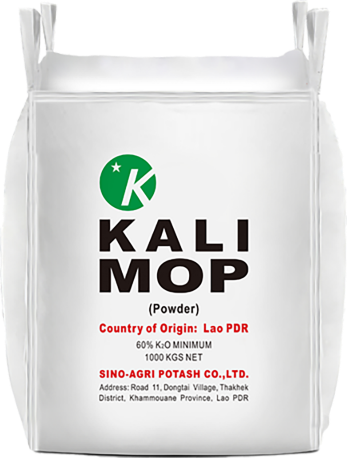

UN sac de béton géant (également connu sous le nom de sac jumbo de ciment ou sac jumbo en bétonLe conteneur en vrac souple (ou squat) est un grand conteneur flexible fabriqué en polypropylène tissé. Il est conçu pour contenir des matériaux de construction lourds, tels que du ciment, du béton sec et du sable, en quantités allant de 500 kg à plus de 2 000 kg. Pour les opérations de levage de charges lourdes, ces conteneurs sont souvent dédiés à des applications spécifiques. GRAND SAC FIBC produits.

Contrairement aux sacs en plastique ou en papier ordinaires, sacs de béton géants Réutilisables, indéchirables et résistantes aux intempéries, ces sangles sont équipées d'anneaux de levage pour chariots élévateurs ou grues, permettant la manutention sécurisée de charges importantes. Conçues pour l'efficacité et la sécurité, elles sont devenues un incontournable de la logistique de construction moderne.

Principaux points à retenir :

GRVS (Grand Récipient pour Grands Récipients Vivants) de grande capacité pour ciment, sable et gravier. Conçu pour le levage de charges lourdes et le transport sécurisé de matériaux en vrac sur les chantiers de construction.

Explorez les GRVS de constructionDans le secteur de la construction, le temps et la précision sont primordiaux. La gestion des matériaux en vrac avec des emballages traditionnels entraîne souvent des déversements, du gaspillage et un surcroît de travail. Sacs de béton géants Abordez ces problèmes directement.

Ils sont suffisamment robustes pour manipuler du ciment et des mélanges de béton en vrac sans se briser, facilitant ainsi le transport et le coulage des matériaux par les ouvriers. Ils préservent également le contenu de l'humidité, l'une des principales causes de détérioration du ciment. Pour des applications spécifiques, vous pouvez consulter notre guide sur Comment fabriquer des sacs de ciment ?.

Au-delà de leur aspect pratique, ces sacs optimisent la gestion logistique en permettant des livraisons en vrac faciles à soulever, à stocker et à empiler. Pour les grands projets, cela se traduit par des coûts de transport réduits et des délais d'exécution plus courts.

Un seul sac jumbo pour ciment Ce système peut remplacer des dizaines de petits sacs en papier ou en plastique. Il réduit la manutention manuelle, accélère le chargement et le déchargement et minimise les déchets d'emballage. Les équipes de construction peuvent ainsi réaliser les travaux de mélange ou de coulage plus rapidement, ce qui représente un gain de temps considérable.

La manipulation de plusieurs petits sacs augmente le risque de troubles musculo-squelettiques et d'accidents. Emballage géant minimise ces risques en réduisant le nombre de trajets et de manutentions manuelles. Les sacs sont compatibles avec les chariots élévateurs et les grues, ce qui rend le transport plus sûr et mieux organisé. Cette sécurité accrue est conforme aux meilleures pratiques décrites dans Un guide ultime pour stocker et manipuler les sacs FIBC en toute sécurité.

Alors que sacs de ciment jumbo Bien qu'elles coûtent plus cher à l'achat que les petits sacs, elles sont réutilisables et plus résistantes. Nombre d'entre elles peuvent servir plusieurs fois si elles sont manipulées correctement. Les économies réalisées sur la main-d'œuvre, le transport et la gestion des déchets compensent rapidement l'investissement initial.

Le développement durable est une priorité croissante dans le secteur de la construction. Fabriqué à partir de polypropylène recyclable, sacs de béton géants Contribuez à réduire les emballages à usage unique et les déchets. Certains fabricants proposent même des sacs écologiques certifiés BRCGS, conformes aux normes environnementales actuelles. Pour des conseils spécifiques sur les tailles, consultez notre guide. Meilleurs sacs en vrac pour différents poids de sacs de ciment.

Les projets de construction sont souvent confrontés à des conditions imprévisibles : poussière, boue, pluie et délais serrés. Emballage géant garantit que les matériaux restent propres, secs et prêts à l'emploi.

La conception tissée du sac permet la circulation de l'air, empêchant ainsi le ciment de s'agglomérer tout en préservant sa facilité d'utilisation. Les entrepreneurs peuvent stocker les mélanges de béton en toute sécurité sur le chantier, sans risque de contamination. Pour ce faire, des matériaux spécialisés comme SAC D'ÉDUCATION PHYSIQUE GAEE Des doublures sont souvent utilisées à l'intérieur du big bag.

De plus, les modernes sacs de béton géants sont dotés de fonctionnalités telles que :

Ce type d'efficacité se traduit directement par une réduction des temps d'arrêt et une meilleure utilisation des matériaux. Pour connaître les meilleures pratiques de chargement et de transport, consultez notre guide associé : Bonnes pratiques pour le transport de sacs de gravier en vrac sur les chantiers de construction.

En utilisant un sac de béton géant Il s'agit de sécurité et de responsabilité. Chaque sac peut transporter en toute sécurité jusqu'à deux tonnes de matériau lorsqu'il est utilisé avec un équipement de levage approprié. Pour garantir la sécurité au travail :

Le développement durable joue également un rôle important. De nombreux fournisseurs produisent désormais sacs de ciment jumbo Grâce à des contrôles qualité certifiés ISO, ces sacs sont durables et génèrent un minimum de déchets. En investissant dans des sacs fiables et réutilisables, les entreprises de construction contribuent à réduire leur empreinte carbone tout en améliorant l'efficacité de leurs projets à long terme.

Le sac de béton géant a révolutionné la gestion des matériaux sur les chantiers. Cette solution simple, durable et écologique permet de manipuler efficacement de grands volumes de ciment et de béton. Du stockage à la livraison, ces sacs contribuent à des opérations plus sûres et à des flux de travail plus fluides. Le groupe XIFA est un fabricant d'emballages de renommée mondiale, proposant des sacs tissés en PP et des sacs en BOPP. GRAND SAC FIBCet des sacs en film PE, garantissant des performances élevées et une personnalisation pour chaque besoin.

Si vous souhaitez améliorer l'efficacité de vos chantiers, découvrez la collection du groupe XIFA. sacs de béton géants et autres solutions d'emballage industriel.