أنواع أقفال الحقائب يشير هذا إلى الطرق المختلفة لإغلاق وتفريغ حاويات FIBC (حاويات التخزين المرنة المتوسطة) أو الأكياس الكبيرة. يحدد الإغلاق مدى أمان تخزين المواد وكفاءة تفريغها. يُعد اختيار تصميم القاعدة المناسب أمرًا بالغ الأهمية لمنع الانسكاب أو التلوث أو فقدان المواد.

استكشف جميع أنواع الأغطية - الفوهة، والمسطحة، والبتلة، والمخروطية - لتناسب احتياجاتك في مناولة المواد والتفريغ بشكل مثالي.

استكشف جميع حلول FIBCيشرح هذا الدليل المكونات الرئيسية لأكياس FIBC أنواع الإغلاقاتنقدم لكم تشكيلة واسعة من الأغطية، بدءًا من الأغطية ذات القاعدة المسطحة وصولًا إلى الأغطية ذات الفوهة والبتلات، لمساعدتكم في اختيار التصميم الأمثل لاحتياجاتكم في مجال التعبئة والتغليف. سواء كنتم تتعاملون مع المساحيق أو الحبوب أو مواد البناء، فإن فهم هذه الأغطية يضمن لكم السلامة والكفاءة والفعالية من حيث التكلفة. للاطلاع على نظرة عامة شاملة على خيارات التعبئة والتغليف الأساسية، تفضلوا بزيارة صفحتنا المخصصة لهذا الموضوع. حقيبة فيبك الكبيرة الحلول.

تُعدّ أكياس FIBC ذات القاع المسطح أبسط أنواع الأكياس المستخدمة في التعبئة والتغليف بكميات كبيرة. تتميز بقاعدة محكمة الإغلاق بدون فتحة تهوية أو منفذ. ولتفريغ محتوياتها، يجب فتح الكيس يدويًا أو إمالته.

الأفضل لـ: أكياس للاستخدام لمرة واحدة وغير قابلة لإعادة الاستخدام حيث يتم التخلص من محتوياتها دفعة واحدة - مثل الرمل أو الحصى أو نفايات البناء الصلبة.

المميزات:

على الرغم من افتقارها لإمكانية إعادة الاستخدام، إلا أن القاعدة المسطحة لا تزال خيارًا شائعًا نظرًا لبساطتها وقوتها.

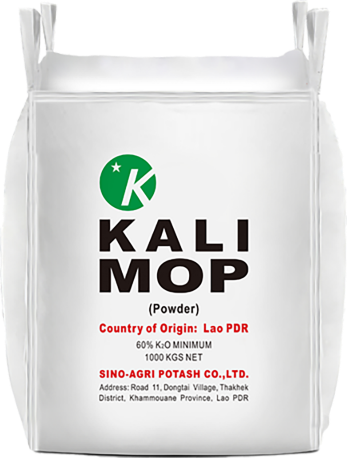

تُعد أكياس FIBC ذات القاعدة الصنبورية واحدة من أكثر الأنواع شيوعاً أنواع أقفال الحقائب تُستخدم للمساحيق والحبيبات. تتميز بوجود فوهة أسطوانية مخيطة في قاعدة الكيس، والتي تعمل كقمع لتفريغ مُتحكم فيه.

فوائد:

يمكن ربط أو إغلاق الفوهة بحبل عند عدم استخدامها، مما يضمن بقاء المواد محمية من الرطوبة والتلوث.

متعلق ب: تعرف على المزيد حول أكياس التسوق الكبيرة ذات القاعدة ذات الفوهة مقابل الأكياس ذات القاعدة المسطحة لفهم أي تصميم يناسب عملياتك.

عند التعامل مع المواد الدقيقة أو الخطرة، يوفر غطاء فوهة مزود بحلقة إغلاق تحكمًا إضافيًا. تعمل حلقة الإغلاق كغلاف ثانوي يلتف حول فوهة التفريغ، ويمكن شده أو إرخاؤه باستخدام آلية ربط، مما يتحكم بدقة في تدفق المواد. يُعد هذا المستوى من التحكم في الغبار بالغ الأهمية، كما هو موضح بالتفصيل في دليلنا. حلول التحكم في الغبار: دليل لتفريغ الأكياس وتعبئتها.

مثالي ل: المساحيق الكيميائية والأسمدة وغيرها من المواد الجزيئية الدقيقة.

لماذا هذا مهم:

يُوصى عادةً بهذا النوع من الإغلاق في الصناعات التي تتطلب التزامًا صارمًا بالمعايير البيئية والسلامة.

تتضمن أكياس FIBC ذات الإغلاق البتلي، والتي تُسمى أحيانًا بالإغلاق النجمي، أغطية قماشية متداخلة (بتلات) مخيطة أسفل فوهة التفريغ. تنطوي هذه البتلات إلى الداخل، لتغطي الفوهة عند عدم استخدامها.

المميزات الرئيسية:

يُعدّ هذا التصميم مفيدًا بشكل خاص للتخزين أو النقل طويل الأمد للمواد الحساسة. تجمع أكياس FIBC ذات الإغلاق البتلي بين السلامة وطول العمر، مما يساعد المصنّعين على تقليل تكاليف الاستبدال وفقدان المواد.

تضيف غطاء الحماية غطاءً خارجيًا من القماش فوق منطقة التفريغ، مما يحمي الفوهة والدرزات من التلف أثناء النقل.

لماذا يتم استخدامه:

يُعدّ هذا التصميم شائعًا في مجال الخدمات اللوجستية وتغليف الصادرات، حيث تُنقل حاويات FIBC عدة مرات قبل وصولها إلى وجهتها. إذا كنت بحاجة إلى أقصى قدر من المتانة للرحلات المتكررة، فضع في اعتبارك المزايا المذكورة في أكياس التسوق الكبيرة للاستخدام مرة واحدة مقابل أكياس التسوق الكبيرة متعددة الاستخدامات.

بعض المنتجات، مثل الطين أو الملاط أو الحبوب الرطبة، لا تتدفق بحرية. يحل كيس FIBC ذو القاعدة المخروطية هذه المشكلة بفضل قاعدته المخروطية التي توجه المواد للخارج بشكل طبيعي بفعل الجاذبية.

فوائد:

يضمن هذا التصميم تفريغًا فعالًا وهو مثالي للصناعات التي تتعامل مع المواد اللزجة أو الكثيفة.

يستبدل قفل B-Lock، المعروف أيضاً بقفل الحبل، العقد اليدوية بآلية قفل آمنة. وهذا يساعد المشغلين على فتح وإغلاق صنبور التفريغ بسرعة وأمان.

المميزات:

يُحسّن هذا النظام سهولة الاستخدام ويعزز السلامة، مما يجعله ميزة شائعة في إنتاج حاويات FIBC الحديثة. ولمعالجة المواد المسببة للتآكل التي تتطلب أقصى درجات الأمان، يُنصح باستخدام حاويات FIBC المصممة خصيصًا لهذا الغرض. أهم فوائد استخدام أكياس FIBC السائبة للمواد الكيميائية.

يؤثر اختيار الإغلاق المناسب ليس فقط على كيفية ملء وتفريغ الأكياس، بل أيضاً على مدى حماية المواد وكفاءة العمليات. تشمل مجموعتنا من المنتجات: حقيبة فيلم بي يمكن دمج البطانات لتعزيز الحماية بغض النظر عن نوع الإغلاق.

الاعتبارات الرئيسية:

فهم هذه الأكياس المرنة القابلة للنفخ أنواع الإغلاقات يساعدك على تحسين كل من التكلفة والسلامة في جميع مراحل دورة التعبئة والتغليف.

فهم أنواع أقفال الحقائب تساعدك هذه الخدمة في اختيار التغليف الذي يتوافق مع متطلباتك المتعلقة بالمواد والسلامة والتداول. بدءًا من التغليف ذي القاعدة المسطحة وصولًا إلى أكياس FIBC ذات الإغلاق المحكم، يخدم كل تصميم وظيفة محددة، مما يُحسّن الكفاءة ويقلل الهدر ويعزز السلامة العامة.

في مجموعة XIFA، نتخصص في أكياس FIBC الكبيرة عالية الجودة، وأكياس البولي بروبيلين المنسوجة، وأكياس BOPP، وأكياس أغشية البولي إيثيلين المصممة خصيصًا للصناعات الحديثة. اكتشف مجموعتنا الكاملة واختر تصميم الإغلاق الأمثل لعملك. ابدأ مشروع التعبئة والتغليف اليوم، فنحن شريكك الموثوق لحلول التعبئة والتغليف بالجملة المتينة والقابلة للتخصيص.

1. ما هو النوع الأكثر شيوعًا لإغلاق الحقائب؟

يُعدّ الجزء السفلي ذو الفوهة هو أكثر أنواع الأغطية استخدامًا لأنه يسمح بتصريف متحكم فيه وتقليل الانسكاب إلى الحد الأدنى.

2. ما هو تصميم قاعدة FIBC الأنسب للمواد اللاصقة؟

يُعدّ القاع المخروطي أو تصميم التفريغ السريع الأنسب للمنتجات اللزجة أو الكثيفة.

3. كيف يمكنني منع الغبار عند تفريغ الأكياس الكبيرة؟

يقلل استخدام غطاء قزحي أو غطاء بتلة من الغبار ويحافظ على المواد محصورة.