適切なFIBCバッグの選び方 問題はサイズだけではありません。安全性も重要です。特にバルク バッグの重量と、バッグが実際にどれだけの荷重に耐えられるかを理解することが重要です。

安全作業荷重 (SWL) という用語は、操作がどれだけ安全かつ効率的であるかを判断するための鍵となります。

この記事では、SWL とは何か、基本的な FIBC バッグの計算方法、そして荷重容量を理解することで高額な事故を防止できる理由について説明します。

穀物、化学薬品、建設資材、肥料などのバルクバッグを調達する場合、正確な数を把握することが重要です。

バルク バッグ重量という用語は、多くの場合、2 つの重要な側面を指します。

これらのバッグは、フレキシブル中間バルクコンテナ (FIBC) とも呼ばれ、大量の材料を輸送するために作られています。

これらのバッグは、コストが低く、再利用が可能で、取り扱いが便利なため、広く使用されています。

しかし、どのバッグにも限界点があり、その限界を知ることは重要です。

SWL とは何ですか? これは Safety Working Load (安全作業荷重) の略で、通常の動作条件下でバッグが運ぶことができる最大安全重量です。

例えば:

FIBC バッグを分類するもう 1 つの方法は、バッグに組み込まれた強度マージンを示す安全係数 (SF) です。

5:1 の安全係数は、バッグがテスト中に破損することなく SWL の 5 倍に耐えられることを意味しますが、それでも規定の荷重しか運ぶことができません。

バルクバッグの容量をより深く理解するために、FIBCバッグの基本的な計算手順を見ていきましょう。まずは、充填する材料の体積と密度を知ることから始めます。

あなたのバッグが次のようなものだとしましょう:

体積 = 1.0 × 0.9 × 0.9 = 0.81立方メートル

かさ密度が約 1,600 kg/m³ の乾燥した砂を袋に詰めるとします。

次に体積と物質の密度を掛けます。

0.81 m³ × 1,600 kg/m³ = 1,296 kg

つまり、SWL が少なくとも 1,300 kg のバッグが必要です。

安全のため、ほとんどの購入者は変動を考慮して 1,500 kg SWL のバッグを選択します。

重要なヒント: 安全性を高め、予期しない重量の変化に対応するために、荷物よりも大きい SWL を持つバッグを選択してください。

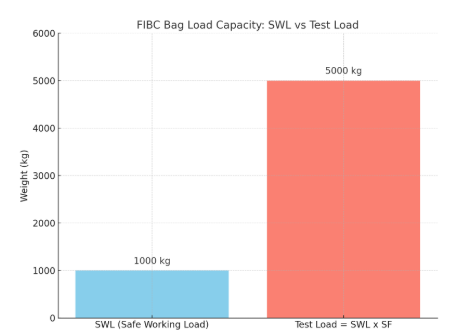

安全係数 (SF) が 5:1 で定格 1,000 kg の FIBC バッグにおける安全作業荷重 (SWL) とテスト荷重の関係を視覚的に示します。

この図により、FIBC 規格における安全マージンがどのように機能するかを理解しやすくなります。

バルクバッグ重量の計算を誤ると、次のような事態が発生する可能性があります。

SWL を理解するということは、数字だけの問題ではなく、安全性、責任、そして業務の効率性を維持することにもつながります。

1. 生地の強度: 厚い ポリプロピレン生地はより強度が高い より高い負荷にも対応できます。

2. ステッチと縫い目クロスコーナーステッチとチェーンステッチにより耐久性が向上します。ダブルステッチの縫い目により、SWL(表面弾性係数)が大幅に向上します。

3. リフティングループループの数と配置 (2 つ、4 つ、またはそれ以上) は、負荷がどの程度均等に分散されるかに影響します。

4. ハンドリング機器: 荷物を持ち上げている間、荷物が安定した状態を保つために、バッグはクレーン、フォークリフト、ホイストなどの取り扱い方法に適合している必要があります。

5. 製品の水分含有量: 濡れた材料や湿った材料は乾いた材料よりも重くなります。SWLを選択する際には、必ずこの追加重量を考慮してください。

すべてのFIBCバッグが同じではありません。SWL容量別に分類した例をいくつかご紹介します。

各バッグは製造工程中に試験され、必要なSWL(安全基準値)と安全係数を満たしていることを確認しています。信頼できるサプライヤーは試験証明書を発行します。

XIFA は、品質と信頼性において高い評価を得ている、信頼できるFIBCバッグのサプライヤーです。当社のバルクバッグは、様々な製品タイプと厳しい産業環境に対応できるよう設計されています。

XIFA は、最小注文数量がわずか 1,000 個であるため、少量から大量までのニーズに対応します。

当社の製品ラインナップには以下が含まれます:

軽量の粉末を梱包する場合でも、高密度の研磨材を梱包する場合でも、XIFA は各バッグが安全性テスト済みであり、国際 SWL 基準を満たしていることを保証します。

バッグは、SWL 評価を確認するために、落下テスト、トップ リフト テスト、積み重ねシミュレーションに合格する必要があります。

これらのテストは、実際のシナリオをシミュレートして、通常の使用ではバッグが破れたり故障したりしないことを確認します。

SWL 準拠のバッグは次のような国際基準に準拠しています。

これらの認証を必ず確認してください。リスクの高い環境では、バッグの強度がスムーズな配送と職場での事故の違いを生む可能性があります。

バルク バッグ重量の取り扱いに関しては、SWL を理解することが不可欠です。

安全で効率的なバルク材料輸送の基盤です。決して推測に頼らず、常に計算し、検証し、信頼できるサプライヤーから購入しましょう。

厳格な安全基準を満たす FIBC バッグをお探しの場合は、XIFA が一貫した品質とパフォーマンスに裏打ちされたカスタマイズ可能なソリューションを提供します。

彼らのバッグは、農業、鉱業、化学、食品加工など、最も過酷な仕事をサポートするように設計されています。