FFS printed bag rolls use reverse printing that traps ink between protective film layers. The method shields graphics from scuffing and moisture during warehouse handling and transport, which helps maintain brand appearance. This also delivers color vibrancy and scratch resistance that lasts longer than surface printing throughout the distribution cycle.

Consumer perception is influenced by how packaging appears on retail shelves.

With surface printing, your branding sits exposed on the outer film where it contacts pallets, conveyor belts, and other packages. That exposure causes fading, scratching, and wear during normal distribution.

Pour pet food or fertilizer brands targeting premium retail segments, damaged graphics undermine the quality positioning you’ve built.

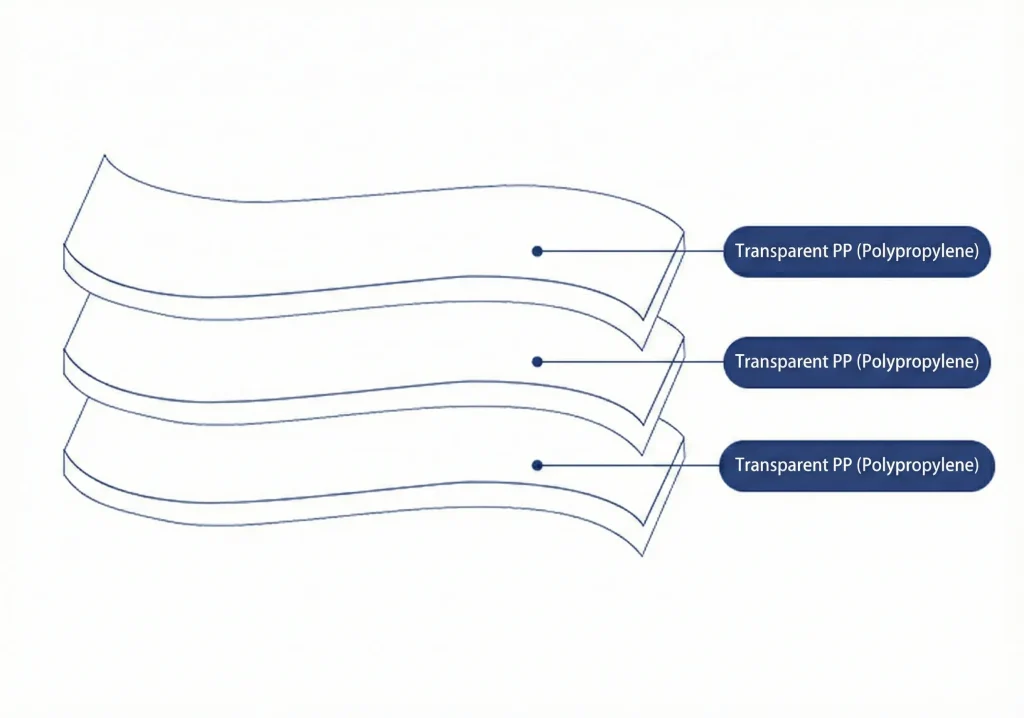

Reverse printing puts ink on the inner surface of clear film and covers it with a protective layer. Consumers view your branding through clear outer film that shields ink from contact damage.

Distribution environments reveal performance differences between these methods.

| Fonctionnalité | Surface Printing | Reverse Printing |

| Ink Location | Outer visible surface | Inner side of clear film |

| Exposure Level | Direct contact with abrasion, moisture | Protected between film layers |

| Appearance Over Time | Degrades with handling | Maintains original vibrancy |

| Durabilité | Scratches and fades | Stays intact through distribution |

| Visual Effect | Standard finish | Glossy appearance with color depth |

| Typical Use | Basic packaging, simple labels | Premium retail products |

How Reverse Printing Works on FFS Film Bags

This approach involves four connected production stages.

The design team prepares graphics digitally and mirrors the image. Mirroring ensures text and logos read correctly when viewed from the front. The reversed artwork then goes to the printing press with color separations matched to your film substrate.

High-resolution gravure presses apply ink to the inner surface of clear film. This printing method provides:

A second material layer bonds to the printed film, sealing ink between the layers. This structure typically combines clear printed film with PE or PP woven fabric that provides bag strength for heavy products.

The laminated material runs through FFS bagging solution equipment. The machine forms bags, fills them with product, and seals them in continuous operation.

Premium product positioning requires packaging that withstands distribution challenges.

Bags for fertilizer or pet food get stacked on pallets, moved through warehouses, loaded into trucks, and displayed in retail environments. FFS bags bags with reverse printing protect your branding from:

Your graphics look identical on store shelves as they did leaving production.

Print viewed through clear protective film creates a glossy surface that attracts attention. The shielded ink maintains color clarity that surface printing loses during distribution. That visual difference reinforces premium positioning when your product sits next to competitors using standard packaging.

Colors, logos, and product information stay sharp and legible. If packaging graphics deteriorate, consumers associate that decline with your product quality. Protected printing preserves brand integrity from manufacturing through purchase.

We operate equipment that delivers the graphic quality premium brands require.

XIFA Group runs an 8-color gravure printing press that produces high-resolution images on FFS film bags. Eight-color capacity supports complex designs with accurate color matching, smooth gradients, and photographic detail that separates premium products from commodity alternatives.

Our design team provides free packaging design services. We develop graphics that work with your brand requirements:

The team understands how different inks perform on various film substrates. That knowledge helps you avoid problems where screen designs don’t transfer properly to printed film. We recommend material combinations that produce the visual effects you’re targeting.

We manage the complete workflow from initial concepts through finished printed rolls ready for your FFS bagging solution equipment. Quality control tracks color consistency across runs so every bag matches your specifications.

Contact our design team to discuss gravure printed FFS rolls for your brand.

Reverse printing protects ink between film layers, preventing scratching and fading during handling.

Reverse printing works with transparent film substrates like BOPP or PE that allow viewing graphics through the clear outer layer. The film must be compatible with the lamination process that protects printed ink.

XIFA Group’s 8-color gravure press can produce complex designs with precise color matching, gradients, and photographic quality. This capability supports premium branding that differentiates retail products.