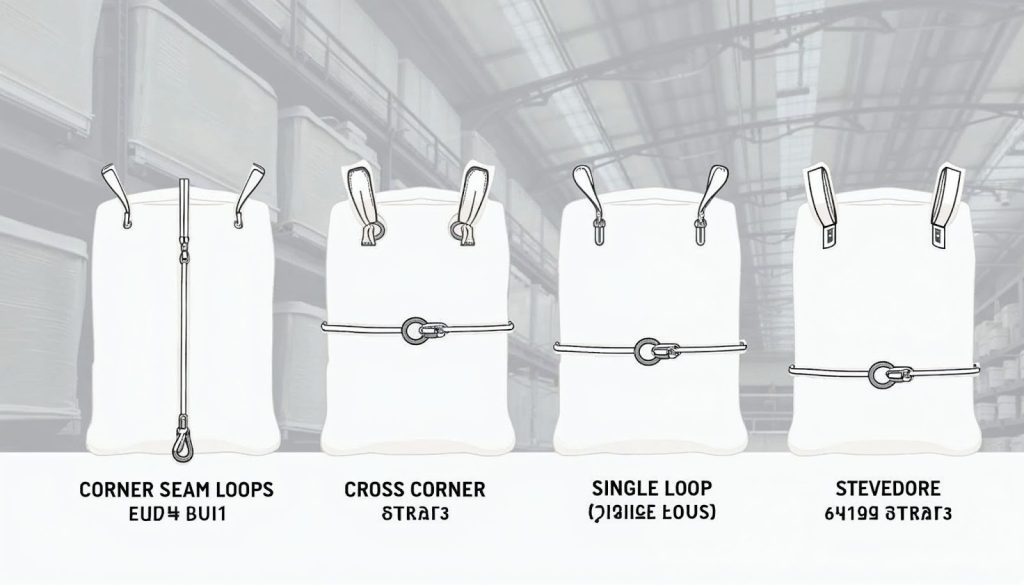

A bulk bag lift loop is the reinforced fabric handle on a Flexible Intermediate Bulk Container (FIBC) that allows the bag to be lifted, moved, and transported. Several types of lift loops are designed for specific applications and lifting equipment. The most common options include corner seam loops, cross corner loops, single and double loop bags, stevedore straps, and tunnel loops.

This guide breaks down each bag loop style so you can choose the best type for your operation—whether you’re using forklifts, cranes, or automated bagging systems. You’ll also learn each configuration’s pros, cons, and best use cases.

Lift loops are not just accessories but critical components of every bulk bag. They determine how bags are picked up, moved, and stored—and can significantly impact handling efficiency, safety, and equipment compatibility.

Most lift loops are made from high-tensile strength woven polypropylene, with each loop rated to handle around 5,000 lbs of tension. Some loops are integrated into the bag’s body, while others are sewn externally. Your choice of loop depends on your material type, handling setup, and automation needs.

Best for: Traditional forklift setups, basic manual handling, and general-purpose use.

Corner seam lift loops are sewn directly into the seams of a 4-panel or U-panel bag. They form a teardrop shape and extend from the top corners.

✔ Most common and cost-effective option

✔ Strong and durable

✔ Suitable for various dry-flowable materials

✘ All four loops must be used simultaneously

✘ May slow down handling if not fully automated

Best for: Faster, more efficient forklift pickup in high-volume operations.

Cross corner loops are sewn across the panel seams of tubular (circular) bags, forming an arched handle that stands upright even when the bag is full.

✔ Loops stay upright—easy for forklift tines to grab

✔ Reduces bag handling time

✔ Compatible with automated systems

✘ Requires circular (tubular) fabric construction

✘ Slightly more expensive than corner seam loops

Best for: Export shipments, cranes, and environments where forklifts aren’t accessible.

Stevedore straps are supporting straps used in addition to standard loops. They connect multiple lift loops, enabling single-point lifting using hooks or cranes.

✔ Allows single- or two-point lifting

✔ Ideal for overhead hoists and port handling

✔ Adds extra lifting flexibility

✘ Adds cost due to extra material

✘ May require special equipment or approval

Best for: Fully automated bagging equipment or low-cost packaging operations.

Single loop FIBC bags use a tubular fabric extension as a built-in loop, eliminating the need for sewn-on handles. These are most common in Europe and best for automated filling and lifting lines.

✔ Most cost-effective design

✔ Simplifies lifting and filling

✔ Requires less sewing—fewer weak points

✘ Not widely used in North America

✘ Less stable if handled manually

Best for: Semi-automated bagging systems and export packaging

Double loop bags are similar to single loop designs but include two lifting points, offering better load balance while still being simple to handle.

✔ Still cost-effective

✔ More stable than single loop during lifting

✔ Compatible with various lifting systems

✘ Still limited in flexibility compared to four-loop bags

✘ Best suited for light to medium loads

Best for: Operations that exclusively use forklifts and need fast turnaround in loading and unloading.

Tunnel loops are fabric sleeves sewn onto the top or bottom of a bulk bag. These sleeves allow forklift tines to slide through directly, offering unmatched ease for forklift operators.

✔ Simplifies forklift handling

✔ Keeps loops from folding or falling

✔ Can be installed on top or base for clearance

✘ Only compatible with forklifts

✘ Not suitable for hook or crane lifting

To choose the right bulk bag lift loop, consider:

Understanding your use case is key to getting both performance and cost-efficiency.

No matter your product or industry, the right bag loop design can make a big difference in efficiency, safety, and cost. Whether you’re handling construction materials, agricultural goods, or chemicals, choosing the right loop type helps reduce downtime and keeps operations running smoothly.

At XIFA Group, we specialize in custom polypropylene and FIBC bulk bags, offering advanced options like single loop FIBC bags, double loop bags, and custom tunnel loops designed to fit your specific operation. With over 25 years of expertise and a commitment to quality and service, we’re here to help you find the best solution—every time.

Download our FIBC Catalog or Get a Quote to explore your options.