A bulk bag dispenser is an essential tool if you’re working in industrial processing, agriculture, or manufacturing and need a reliable solution for handling large quantities of bulk materials. These systems—super sack or big bag dispensers—help you unload FIBC (Flexible Intermediate Bulk Container) bags efficiently and safely. In this guide, you’ll learn what a bulk bag dispenser is, how it works, what features matter, and how to choose the right one for your needs. We also cover essential product configurations, common standards, and answer the most asked questions.

A bulk bag dispenser is a piece of industrial equipment used to unload dry materials from large FIBC bags (also called jumbo bags or super sacks). These dispensers allow gravity-assisted or controlled flow of powders, granules, or flakes into downstream equipment like conveyors, mixers, or packaging machines.

Handling tons of material manually is not only time-consuming but also risky. A bulk feed bag dispenser automates the process, boosting your operation’s speed and accuracy. A bulk bag dispenser ensures efficient and clean material flow with minimal manual effort, no matter the material—food ingredients, plastic pellets, cement, or seeds.

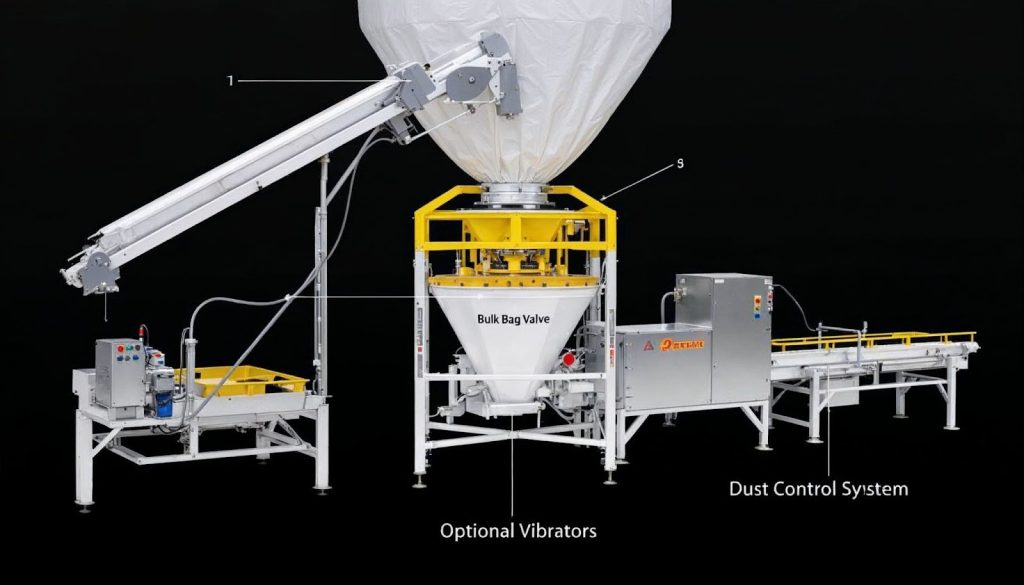

A standard setup involves a steel support frame that holds the FIBC bag above a discharge station. A bulk bag spike unties or pierces the bulk bag valve or spout, allowing the material to flow out. Depending on the product’s nature, the flow can be regulated using a gate valve, slide gate, or pneumatic actuator.

Advanced units include vibration pads to ensure full discharge, dust collection ports for clean operation, and bulk bag dispenser valves that prevent over-dispensing.

Bulk bag dispensers come in many variations, but most share these core parts:

Some models offer enclosed systems, explosion-proof designs, or stainless steel builds for food and pharmaceutical use.

Dispenser systems must match the weight capacity of the FIBC bags they support. Most FIBC bags hold between 500 kg and 2000 kg. Bulk bag dispensers usually support a load range of 1 to 2 tons. When batching accuracy is crucial, look for units with integrated weighing cells.

International standards such as ISO 21898 (for big bag safety) guide the construction and material of the bags, while dispenser design must align with operational safety protocols like OSHA and CE compliance.

These machines are used across industries like:

Their adaptability makes bulk bag dispensers preferred for high-volume, solid-material processing.

Several factors determine the right dispenser for your facility:

Investing in the right equipment minimizes downtime and ensures long-term productivity.

A bulk bag dispenser is a reliable, scalable solution for improving material flow, workplace safety, and operational efficiency. You can streamline production and reduce costs with the right setup, including bulk bag valves and spike-fed systems.

XIFA Group specializes in high-quality FIBC bags and dispensing equipment tailored to industrial needs. With over 25 years of experience and fully integrated production, we serve industries such as agriculture, construction, food-grade, and chemical sectors.

For more details, visit our website at xifagroup.com. To explore our full range of FIBC products and configurations, access our catalog here.