Высококачественная упаковка в пакеты FFS оптимизирует вашу цепочку поставок за счет снижения затрат на материалы и требований к складским площадям, а также увеличения скорости упаковочной линии. Рулоны пакетов FFS стоят дешевле, чем готовые пакеты, и поддерживают автоматизированное производство, что сокращает потребность в рабочей силе и потери материалов на всех этапах вашей работы.

Большинство предприятий по упаковке удобрений сталкиваются с одними и теми же проблемами, связанными с запасами.

Готовые пакеты занимают огромное количество складского пространства. На типичном предприятии под пустые упаковочные материалы отводится от 30 до 401 тонны (6 тонн). Для каждого размера пакетов необходимы отдельные складские запасы, а эти стопки плоских пакетов громоздки и с ними сложно эффективно обращаться.

Капитал замораживается в складских запасах упаковочных материалов. Когда вы заказываете готовые пакеты в количествах, достаточных для получения приемлемой цены, вы храните на балансе запасы упаковочных материалов на месяцы, прежде чем они начнут приносить доход.

Рулоны пленочных пакетов FFS решают обе проблемы благодаря своему компактному формату. Один поддон с рулонами пленки содержит материал, эквивалентный тысячам готовых пакетов, но занимает гораздо меньше места. В помещении, где раньше хранились пустые тканые мешки, можно разместить запасы упаковочного материала на несколько недель.

Чтобы показать, как эти различия проявляются в реальных операциях, мы создали таблицу, сравнивающую ключевые факторы цепочки поставок.

| Фактор цепочки поставок | Рулоны FFS для пакетов | Готовые сумки |

| Стоимость материалов | 30-50% ниже | Более высокая цена из-за затрат на переработку. |

| Место для хранения | 60% меньше складской площади | Требуются специально отведенные зоны для хранения. |

| Гибкость управления запасами | Один рулон = несколько размеров | Отдельный склад для каждого необходимого размера. |

| Срок выполнения заказа | Сокращено для рулонов пленки | Для переоборудованных сумок требуется больше времени. |

| Риск устаревания | Низкий (легко регулируется размер) | Высокий (приверженность определенным форматам) |

| Стоимость доставки | Нижний (компактный) рулон | Более высокие (пустые мешки большого объема) |

| Замороженный капитал | Меньше инвестиций в складские запасы. | Необходим дополнительный оборотный капитал |

Пленочные упаковочные мешки для удобрений FFS обладают специфическими эксплуатационными характеристиками, необходимыми для отрасли производства удобрений.

Многослойная полиэтиленовая конструкция создает эффективный влагозащитный барьер. Удобрения гигроскопичны, поглощая воду из воздуха и влаги. Когда влага проникает в упаковку, продукты слипаются, теряют питательные свойства и становятся трудноукладываемыми. Барьерные свойства пленки FFS предотвращают проникновение влаги, вызывающей эти проблемы.

Термосварные затворы создают герметичную упаковку:

Материал выдерживает физические нагрузки на протяжении всего процесса транспортировки. Прочность на разрыв и устойчивость к проколам означают, что пакеты выдерживают автоматизированные линии наполнения, складирование и неаккуратную транспортировку без разрывов.

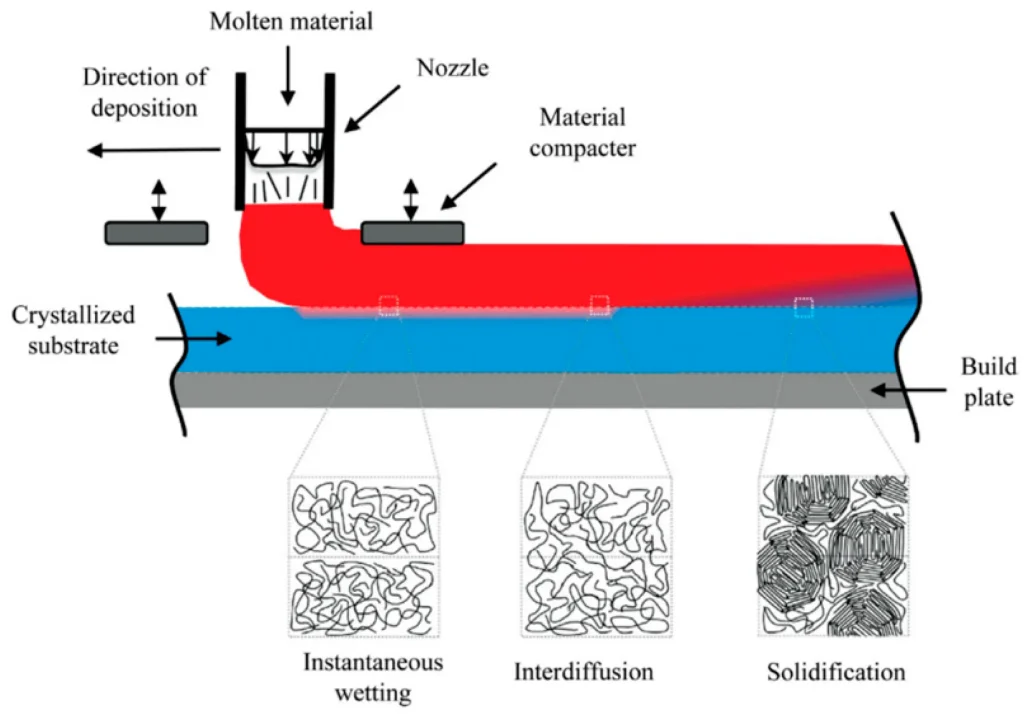

Работа трубчатых упаковочных машин FFS позволяет осуществлять упаковку значительно быстрее, чем традиционные методы.

Процесс формования, наполнения и запечатывания позволяет создавать упаковки, наполнять их и запечатывать в одной автоматизированной последовательности. Такой интегрированный подход обеспечивает скорость более 100 пакетов в минуту. При использовании готовых пакетов производительность обычно достигает 40-60 пакетов в минуту, поскольку рабочим требуется время для размещения каждого пакета на фасовочном оборудовании.

Эта разница в скорости накапливается на протяжении всего процесса:

Время простоя производства также сокращается при использовании рулонов FFS. Вы заряжаете один рулон пленки, которого хватает на несколько часов, вместо того, чтобы постоянно пополнять стопки заранее подготовленных пакетов, за которыми работникам приходится часто следить и которые нужно часто заполнять.

Рыночные требования меняются, и ваша упаковка должна быстро адаптироваться.

При использовании готовых мешков изменение формата создает проблемы с запасами. Когда предпочтения покупателей смещаются с 50-килограммовых мешков на 25-килограммовые, в итоге образуются устаревшие запасы, которые либо нужно продавать со скидкой, либо утилизировать. Заказ новых размеров мешков означает ожидание производства и доставки, при этом вы потенциально можете потерять продажи.

Системы упаковки в пакеты FFS обрабатывают изменения формата за счет регулировки оборудования. Один и тот же рулон пленки позволяет производить пакеты разных размеров в зависимости от настроек оборудования. При изменении спроса вы корректируете параметры производства, вместо того чтобы заказывать совершенно новые упаковочные материалы.

Такая гибкость предоставляет ряд преимуществ:

Региональная персонализация также становится более практичной. Вы можете производить небольшие партии упаковки, адаптированной под конкретный регион, или сезонные рекламные дизайны без больших минимальных объемов заказов, которые требуются для готовых пакетов.

Эффективность цепочки поставок ничего не значит, если товары доставляются поврежденными.

Влагозащитные свойства пленки FFS имеют значение для удобрений. При оценке варианты упаковочных материалов для удобренийРассмотрите, как воздействие влаги во время транспортировки по прибрежным или тропическим регионам влияет на качество продукции. Многослойная конструкция блокирует влажность даже во время длительной транспортировки, где влага в противном случае испортила бы продукцию.

Встроенные в пленку УФ-стабилизаторы позволяют хранить ее на открытом воздухе без преждевременного разрушения:

Компактный формат рулонов также минимизирует повреждения упаковочных материалов при транспортировке. Рулоны пленки менее подвержены разрывам, проколам и воздействию погодных условий, которые могут сделать готовые пакеты непригодными для использования еще до того, как они попадут на линию розлива.

Подделка и фальсификация создают риски для цепочки поставок, выходящие за рамки простого ущерба для продукции.

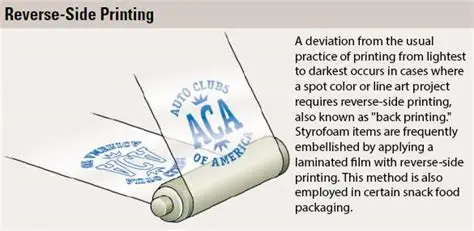

Технология упаковочных пакетов FFS обеспечивает комплексную защиту, недоступную для традиционной упаковки. Рулоны пакетов FFS с высококачественной обратной печатью располагаются под пленочным слоем, где графика устойчива к царапинам и воздействию погодных условий, что затрудняет ее копирование или изменение.

Системы отслеживания интегрируются в производство без усложнения. Прочные QR-коды или серийные метки, наносимые во время формирования пакетов, обеспечивают отслеживание по всей цепочке дистрибуции. Клиенты могут проверить подлинность продукции, сканируя коды, которые связаны с вашей базой данных аутентификации.

Герметичные пломбы обеспечивают мгновенные доказательства попытки вскрытия. Термосварные застежки демонстрируют видимые повреждения при попытке вскрытия, в то время как прошитые тканые мешки можно разрезать и зашить заново, практически не обнаружив повреждений.

Выбор правильного производителя пакетов FFS определяет, добьетесь ли вы этих улучшений в цепочке поставок.

Группа компаний XIFA производит высокоэффективные пленки FFS и готовые мешки, разработанные для удовлетворения потребностей отрасли производства удобрений. Наша продукция выдерживает сложные условия, с которыми сталкивается упаковка при хранении и транспортировке на большие расстояния.

Что дают наши материалы:

Прямые поставки с завода и производственная мощность в 400 миллионов мешков в год обеспечивают стабильные сроки выполнения заказов и надежное наличие запасов. Мы также принимаем срочные заказы с доставкой в течение 4-6 дней, что минимизирует простои производства, когда вам срочно нужны упаковочные материалы для бесперебойной работы вашего предприятия.

Мы предлагаем индивидуальную настройку размеров, плотности ткани (GSM), цвета и печати с помощью собственных дизайнерских команд. Наш контроль качества включает QR-коды для отслеживания партий. Глобальная экспортная поддержка включает оперативное послепродажное обслуживание с выездной помощью при необходимости.

Свяжитесь с нашей командой, чтобы обсудить решения FFS по использованию рулонных пакетов, которые оптимизируют ваши упаковочные операции.

Рулоны мешков, специально предназначенные для системы FFS, стоят на 30-501 тонну дешевле, чем готовые мешки, занимают на 601 тонну меньше складского пространства, сокращают трудозатраты за счет автоматизации и минимизируют отходы материалов благодаря точной резке.

Пленка FFS обеспечивает герметичный влагозащитный барьер и устойчивость к ультрафиолетовому излучению при хранении на открытом воздухе. Она также обладает высокой прочностью на разрыв для тяжелых грузов и поддерживает высокоскоростное автоматизированное наполнение, недоступное для традиционных тканых мешков.

Да, системы FFS переключаются между размерами мешков путем регулировки настроек машины, а не путем пополнения запасов мешков, что обеспечивает гибкость и позволяет быстро реагировать на меняющиеся рыночные требования.