FFS bag for resin operations delivers two critical advantages: automated packaging speeds exceeding 1,000 bags per hour and hermetic seals that keep moisture out. If you’re packaging granular resins, these capabilities directly impact your production throughput and product quality in ways traditional woven bags cannot match.

Packaging granular resin isn’t like packaging other industrial products.

The material flows freely, which means you need filling systems that can handle high speeds without creating dust or spillage. Resin also degrades when exposed to moisture or humidity, so any gaps in your packaging let air and water penetrate. That causes clumping, discoloration, and chemical property changes that make the product unusable.

Traditional woven bags create problems on both fronts. The stitched closures leave needle holes that allow moisture infiltration.

Manual filling operations can’t keep pace with modern production volumes. You end up with bottlenecks at the packaging line that limit your overall facility output.

FFS technology solves these issues by combining bag formation, filling, and sealing into one automated sequence.

The system creates bags from continuous film rolls, fills them at high speed, and heat-seals them closed without any stitching. This means no needle holes and no manual handling slowing down your line.

The shift to FFS packaging reflects broader changes in how the industria química operates.

Labor Costs and Availability

Finding workers for packaging operations has become harder and more expensive. FFS automation reduces the number of people you need on the packaging line. One operator can manage equipment that would otherwise require three or four workers manually positioning and sealing bags.

Regulatory Pressure on Product Integrity

Safety regulations for chemical handling require packaging that prevents leaks and contamination. If product escapes during transport or storage, you face liability issues and regulatory penalties. FFS packaging using multi-layer polyethylene or polypropylene films creates barrier properties that traditional woven structures cannot achieve:

Market Expectations for Sustainability

Customers increasingly demand recyclable packaging. FFS systems work with mono-material films that recycling facilities can process, unlike composite woven bags that mix materials and end up in landfills.

The technology delivers specific performance benefits when you apply it to granular resin packaging.

Production Speed That Changes Your Capacity

Vertical FFS or Horizontal FFS systems handle thousands of bags per hour. That means you can package more product in a single shift without adding packaging lines or expanding your facility footprint.

The speed advantage compounds when you consider changeovers.

If you need to switch from 25kg bags to 50kg bags, you adjust machine settings rather than swapping out entirely different pre-made bag inventories. This flexibility reduces downtime between production runs.

Material Strength for Rough Distribution Environments

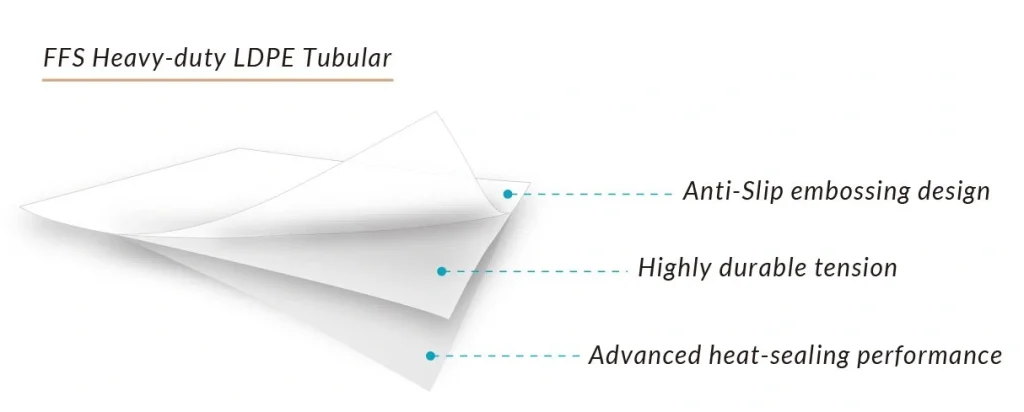

Chemical products often get stored outdoors or transported long distances through varying climates. FFS films are engineered with specific protective properties:

These characteristics mean bags maintain integrity even when stacked six pallets high or left in uncovered storage yards.

Pallet Efficiency That Reduces Freight Costs

Block-bottom FFS bags create square packages that stack efficiently on pallets. You can fit more product per pallet compared to pillow-style bags that leave gaps and irregular surfaces. That translates directly to lower freight costs per unit when shipping to customers.

Anti-slip embossing on the film surface keeps stacks stable during transport. This reduces the risk of pallet collapse or load shifting that damages product and creates safety hazards.

The economics become clear when you break down actual costs.

Film rolls for FFS systems cost 50% less than purchasing equivalent quantities of pre-made composite woven bags. You’re buying raw material rather than finished goods, which removes conversion costs and handling margins from the pricing.

Labor expenses drop because automation handles the work. You need fewer people per shift and those workers focus on equipment monitoring rather than repetitive manual tasks. This reduces both wage costs and workplace injury risks.

Material waste also decreases. FFS equipment cuts bags precisely from continuous rolls with minimal scrap. Pre-made bag operations generate waste through damaged inventory and obsolete sizes when specifications change.

Chemical industry regulations require tracking products through the supply chain.

FFS systems integrate printing and labeling directly into the packaging process. QR codes get applied to each bag as it forms, creating a permanent mark that links to your batch database. Customers can scan these codes to verify product origin and access safety data sheets.

This capability matters when dealing with hazardous materials or regulated substances. You can demonstrate compliance with tracking requirements without adding separate labeling operations that slow production.

Matrix FFS for sand bags and similar demanding applications extends the core technology to extremely heavy or abrasive materials.

This approach uses reinforced film structures and modified filling systems. If you’re packaging products with different flow characteristics or higher weights, the matrix configuration adapts while maintaining automation benefits.

We’ve worked with chemical manufacturers long enough to understand what your packaging needs to accomplish.

XIFA Group provides FFS packaging solutions designed specifically for resin and chemical applications. Our materials handle the conditions your products face during storage and distribution.

Our films offer:

Our production capacity of 400 million bags annually means stable supply even for large-volume operations. We also accept urgent orders with 4-6 day delivery when you need materials quickly to avoid production downtime.

If you’re also packaging chemicals in bulk quantities, understanding the benefits of FIBC bulk bags for chemical applications can help you decide when bulk containers make more sense than individual bags. Some operations use both formats depending on customer requirements and shipping destinations.

We offer customization in film thickness, dimensions, and printing to match your specific requirements. Quality control includes QR code integration for traceability. Contacta con nuestro equipo to discuss FFS heavy film fertilizer packaging bag options and resin packaging solutions that fit your production needs.

Preguntas más frecuentes

Why does granular resin need FFS packaging instead of traditional bags?

Granular resin requires high-speed automated filling that traditional manual operations cannot achieve and needs hermetic moisture barriers that stitched woven bags cannot provide. FFS packaging delivers both through integrated automated systems.

How much can FFS packaging reduce costs compared to woven bags?

FFS film costs approximately 50% less than equivalent pre-made woven bags and requires fewer workers per packaging line. Material waste also drops through precision cutting from continuous rolls.

Can FFS packaging handle chemical industry safety and tracking requirements?

Yes, FFS systems create hermetic seals that prevent product leakage and support integrated QR code printing for regulatory traceability throughout the distribution chain.