Choose duffle top bulk bags if you need flexibility to handle different products with various filling methods. Pick spout tops if you’re filling fine powders or chemicals that need precise control and contamination protection. Go with open tops if you’re handling construction materials like sand or debris where speed and low cost matter more than protection. The right choice depends on what you’re filling, how you fill it, and whether your products need protection during transport.

Flexible intermediate bulk containers, commonly called FIBC bags or super sack bags, are industrial-strength containers designed to handle 2,000 to 4,000 pounds safely. The top design determines how you fill the bag, what equipment you need, and how well your products stay protected.

These jumbo bulk bags serve industries from food processing to construction, but each application requires different features. The key is matching the bag design to your specific filling method and product requirements.

When you’re shopping for FIBC bags, you’ll have three main options to choose from. Below, I’ve broken down each type so you can quickly see which one matches your needs and budget.

Open-top bags are exactly what they sound like – completely open containers with no closure mechanism. These jumbo bulk bags work like giant, industrial-strength garbage bags that you fill from the top.

These bags excel when you need quick filling and don’t worry about protecting contents from weather or dust. Construction companies love them for hauling debris, sand, and rock because they’re affordable and you can dump materials in quickly with equipment like excavators or conveyors.

Key features:

The main limitation of open top designs is the lack of product protection. Materials remain exposed to moisture, dust, and other environmental factors, making them unsuitable for sensitive products requiring contamination control.

Spout top designs feature a cylindrical tube (typically 14 inches wide and 18 inches long) sewn onto a flat base that covers the bag opening. This bag spout connects directly to your filling equipment, creating a closed system that prevents spillage and contamination.

These super sack bag filler systems work exceptionally well for businesses handling fine powders, chemicals, or food ingredients. The controlled filling process minimizes waste, which saves money when you’re dealing with expensive materials. You can tie off the spout after filling to protect the contents during transport and storage.

Key advantages:

The trade-off is that you need compatible filling equipment that connects to the spout. This makes them less flexible than other designs, but the precision and cleanliness often justify the investment for businesses handling sensitive materials.

Duffle top bulk bags feature a tubular skirt sewn directly to the bag’s top edge, combining the accessibility of open tops with the closure capability of spout designs. This configuration offers the most versatile filling and handling options.

The duffle top design allows full access to the bag’s interior during filling while providing secure closure for transportation and storage. Unlike spout tops, duffle tops don’t require specific equipment connections, making them adaptable to various filling methods.

Key advantages:

The main drawbacks of duffle top bags are higher cost and less suitability for very dusty materials since the top remains open during filling.

The decision comes down to what you’re filling, how you fill it, and whether your products need protection. Most factories can narrow down their choice by answering a few simple questions about their operation.

Quick Decision Guide

| If You’re Handling… | Choose This Type | Why |

| Sand, gravel, construction debris | Open Top | Fastest filling, lowest cost, weather exposure isn’t a problem |

| Fine powders, chemicals, food ingredients | Spout Top | Prevents contamination and waste, connects to equipment |

| Multiple different products | Duffle Top | One bag type works for various materials and filling methods |

Key Things to Consider

Filling material. Fine powders and dusty materials work best with spout tops because they prevent spillage and contamination. If you’re handling granular materials like seeds or pellets, duffle top bulk bags give you flexibility. For larger solids like rubble or sand, open tops get the job done cheapest.

Filling method. If you have dedicated filling equipment, spout tops connect directly to your super sack bag filler and give you precise control. If you use different filling methods or don’t have specialized equipment, duffle tops work with hoppers, chutes, or manual filling. Open tops work with any filling method but offer no dust control.

Protection requirements. If your products need protection from weather or contamination during shipping, you need closable bags (spout or duffle tops). If protection doesn’t matter, open tops save money.

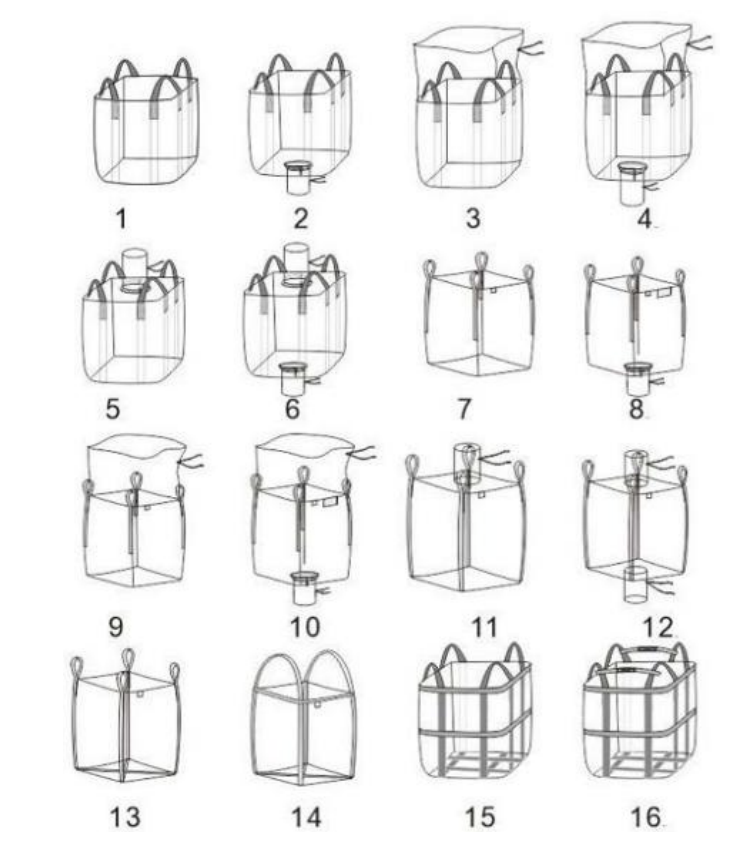

Beyond the three basic top designs, modern FIBC manufacturers offer numerous customization options. For example, XIFA’s FIBC bags support multiple opening methods and can be tailored to match your specific operational needs.

Some bags include internal baffles that maintain shape during filling and improve stability during transport. Many manufacturers also offer specialized discharge options, including various sack tops configurations for controlled emptying.

Then there are anti-static versions that prevent electrical buildup when handling flammable materials. Another option is conductive designs that provide enhanced electrical safety for specialized applications. Want extra protection for outdoor storage? Food-grade liners protect edible products from potential contamination and moisture.

Whether you need a standard FIBC super sack or something with specialized features, you have plenty of options.

Experienced suppliers provide valuable guidance in selecting appropriate designs and features for your applications. They can recommend modifications, suggest testing approaches, and help optimize your entire material handling process.

Many offer sample quantities so you can test different designs with your actual products and equipment. This testing approach helps avoid costly mistakes and ensures optimal performance before committing to large orders.

For detailed specifications and customization options, review comprehensive product catalogs like XIFA’s FIBC bag catalog that show various construction options, dimensions, and special features available.

Before ordering, calculate your volume requirements and weight limits. Standard bags handle 2,000 to 4,000 pounds, but you need to know your product’s bulk density to determine actual capacity. A cubic foot of sand weighs much more than a cubic foot of plastic pellets.

Consider starting with a mixed order if you handle different products. This lets you test various designs before committing to large quantities. Many suppliers offer sample bags or small quantities for testing purposes.