Flexible Intermediate Bulk Containers (FIBCs), or as it is also known as bulk bags, super sacks, or big bags, the commodities are very useful in the transport and storage of dry, free-flowing powders and other materials. Therefore, different handling techniques should be used for effective material transfer. This article is going to describe the different bulk bag discharge systems, their features, and where they are used.

FIBCs or bulk bags are large flexible containers made of woven polypropylene for bulk flowable products routing from 500 Kg – 2000 KG. They are very common in industries such as agriculture, construction, chemical, food, and mining. Material characteristics influence the selection of the types of discharge systems, methods of use, and re-use.

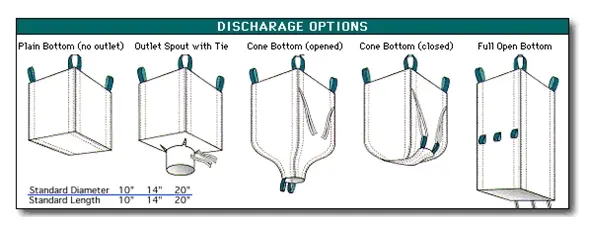

The plain-bottom type of FIBC, otherwise known as a flat bottom bulk bag, is the most straightforward of designs and hence the most cost-effective bulk bag. However, since the base should be cut off to allow the good to be discharged, this design can only be used to discharge one batch of goods. This design is useful in those processes which do not involve discharge operations or discharge operations which are to be done quickly just once.

Discharge spout FIBCs are the most-used among all bulk bag types. The bag can be reused without damaging it during the discharge since the spout is integrated into the construction of the bag. The diameter of the spouts is usually 14 inches, whereas the length is about 18 inches, although it can be modified according to the specification.

A conical discharge spout is a practical feature to assist the thorough emptying of the bag’s contents. This type solves a frequent problem in normal FIBCs whereby material remains at a diagonal. The conical profile eliminates waste by allowing the discharge of materials from the lower end of the bulk bag.

This type involves a robotic discharge spout, including a flap that closes around the spout. This flap is crucial in avoiding dirt around the spout, thus preventing spout contamination, making it highly applicable in sachet products that need to be cleaned, such as the food and pharmaceutical industry.

The duffle-bottom type is characterized by a drawstring system at the base of the bulk bag within the FIBC bulk bag. Such a design is ideal for regulating the discharge of materials as it is controlled and is most definitely useful where the flow rate has to be adjusted. It is widely considered a popular choice in industries that handle granular or powdered materials.

Diaper bottom FIBCs are designed such that the bottom part of the bag is cut inwards and sealed up. This type is good for holding fine powders or other material that escapes. When it is time to discharge, the hidden bottom portion, which has folds, unfolds and lets the basic contents pour out in a calm and orderly manner.

The second type is the advanced iris closure, which is also a type of discharge but consists of a circular opening movement to that of a camera opening. This is a more advanced feature than the previous types as it can effectively manage the whole discharge process without the overriding of important factors such as the amount of product that ought to be dispensed for a specific purpose.

Choosing the right discharge type for your FIBC bulk bags is important since it is the first step to better handling and processing of your material. Bear in mind these considerations:

Material features: Different products flow differently. For example, a diaper bottom or iris closure may be needed for special fine powder-controlled-diaphragm-type flow applications.

Industry requirements: In most cases, food and pharmaceutical manufacturing plants must employ discharge types with flaps to reduce the risk of contamination.

Reusability needs: For those who would like to use the bulk bags more than once, discharge spouts or iris closures would be convenient rather than ordinary bottom bags.

Discharge rate: Some processes may call for a quick wear-down. Some may require steps to be controlled as little as possible. Consider such a case as may be.

Compatibility with the existing equipment: Make sure that such cupboards correspond with the type of discharge you have chosen and your – material handling systems.

Why do you need to know the different types of bulk bag dischargers? Such knowledge is imperative for the optimization of any material handling system. From the simple yet economical plain bottom to the accurate and reliable iris closure, every bulk discharger has its own advantages for different people in their various fields. Such considerations guide you in choosing the most suitable discharge type for your FIBC bulk bags.

Remember that if the operative decision is done correctly, the performance will increase significantly, the amount of wasted product will decrease for good, and so will the risk to the people by providing safe working conditions. If you are not sure which type of option fits you better, do not hesitate to ask FIBC’s manufacturing companies or suppliers, and their advice will be helpful.