FFS (Form-Fill-Seal) packaging is an automated system that produces bags from film rolls, adds product, and closes them in one continuous cycle. The technology streamlines three separate operations into a single machine, cutting down on handling time and worker contact while boosting output speeds for items like chips and grain products.

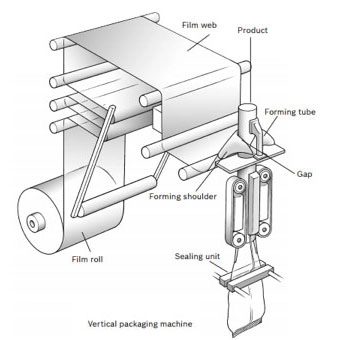

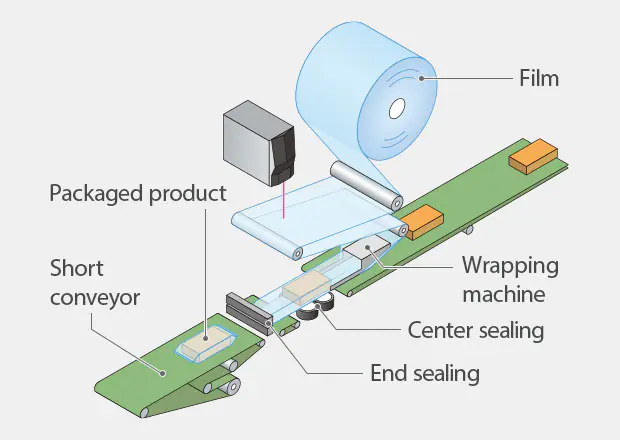

FFS technology uses film reels and coordinated mechanical components to build complete packages without interruption. The system pulls material from a roll, molds it into containers, adds measured amounts of product, then bonds the openings shut with thermal sealing.

Two machine types dominate the market: vertical units that drop product downward using gravity, and horizontal configurations built for items needing careful positioning.

Because everything occurs inside a closed chamber, the product never touches open air or human hands. This matters especially when packing food items or medical supplies where cleanliness standards are strict.

FFS production moves through three connected stages that convert raw film into filled, sealed packages.

Building the Container

Machinery draws film through guides and heaters that mold it into tubes or flat envelopes. Controlled temperature and compression create the bag walls before any product enters.

Adding Product

Various dispensing mechanisms handle different material types:

Getting the fill amount right affects both product consistency and packaging waste.

Closing the Package

Motorized jaws press and heat the bag edges to form airtight bonds. Current systems modify settings in real-time to keep seals strong even when running over 200 units per minute.

FFS equipment creates multiple bag designs suited to different product types and display preferences.

Common configurations include:

All styles accept custom artwork and handle attachments while keeping automation benefits intact. When comparing manual versus automated filling approaches, consider how bag format affects equipment selection.

Two distinct equipment layouts handle different product categories and operational requirements.

VFFS (Vertical Form-Fill-Seal)

Vertical equipment drops product downward through formed tubes, which works well for materials that flow freely. Common applications include sugar, plant nutrients, frozen vegetables, seasoning blends, and crunchy snacks. These machines take up less floor space and connect easily with weighing instruments.

HFFS (Horizontal Form-Fill-Seal)

Horizontal equipment moves product sideways into pouches, which suits solid pieces where positioning matters. Typical uses include cookies, bags needing zipper additions, and items that would break if dropped. This layout accommodates more elaborate pouch constructions for higher-end retail products.

FFS film describes the layered sheet materials that form-fill-seal equipment transforms into packages.

These materials typically blend polyethylene, polypropylene, or BOPP sheets selected for particular characteristics:

Choosing appropriate film depends on what you’re packing and where it’s stored. Pairing the correct material thickness and construction to your products can also cut costs while improving protection.

FFS packaging addresses several challenges across food, pharmaceutical, chemical, and agricultural sectors. Here are some of the factors behind its widespread adoption in modern manufacturing.

Production Speed

FFS equipment runs between 60 and 200+ cycles per minute, far exceeding hand-packing rates. Higher throughput means more units finished per shift with fewer workers needed.

Material Efficiency

Buying film on rolls costs 15 to 30 percent less than purchasing ready-made pouches. Rolls also occupy less storage space than stacked empty bags.

Contamination Control

The sealed automated process keeps outside particles and bacteria away from products. This enclosed approach helps maintain quality from filling through final closure.

Production Flexibility

FFS machines process everything from fine talc to chunky cereals and pourable liquids. The same line can switch between different products using quick adjustment procedures.

Selecting an experienced packaging partner ensures reliable production and consistent quality.

XIFA Group is a high-end woven plastic packaging manufacturer providing wholesale services for FFS film and FFS bags. With 25 years of experience and assets of 250 million RMB, XIFA supports QR code traceability and customized designs, is internationally certified, and offers on-site after-sales service. Contact our packaging specialists to discuss your FFS packaging requirements.

FFS stands for Form-Fill-Seal, an automated packaging method that forms bags from film, fills them with product, and seals them in one continuous operation.

FFS bags package granular products like rice and fertilizers, powders such as flour and detergent, snacks, liquids, and pet food across food, chemical, and agricultural industries.

FFS production is an integrated manufacturing process where packaging machines create, fill, and seal bags automatically from film rolls, achieving high speeds with minimal contamination risk.