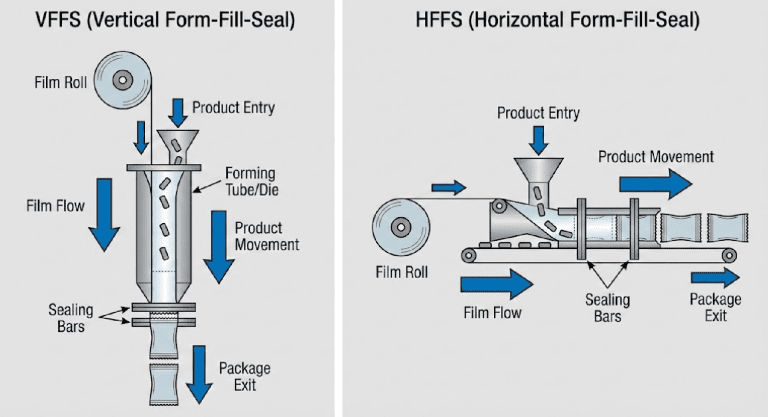

Vertical FFS bags are ideal for free-flowing products such as powders and granules. Meanwhile, horizontal formats work best for solid items or premium retail packaging. The right choice hinges on your product characteristics and the bag formats your market demands.

Here’s how vertical and horizontal FFS machines differ across key operational factors.

| Factor | Vertical FFS Bagging Machine | Horizontal FFS Bagging Machine |

| Orientation | Operates vertically, uses gravity | Operates horizontally with conveyor |

| Suitable Products | Powders, granules, liquids, small loose items | Solid items, irregularly shaped products, fragile goods |

| Common Bag Formats | Pillow bags, gusseted bags, quad seal bags | Stand-up pouches, flat sachets, retort pouches, zipper bags |

| Production Speed | Up to 200+ bags/minute | High speeds but slower for indexing fills |

| Floor Space | Compact footprint, needs ceiling height | Requires linear floor space |

| Initial Cost | Lower equipment investment | Higher upfront cost |

| Product Handling | Products drop via gravity | Gentle placement on conveyor |

| Best For | High-volume commodity products | Premium retail products, delicate items |

What you’re packaging determines which machine can handle it.

Free-flowing products like sugar, coffee grounds, or plastic pellets work with vertical systems. The material drops through a tube former into bags below, which means you get speeds over 200 bags per minute. That efficiency comes from using gravity instead of mechanical systems to move product.

Solid or fragile items need horizontal machines. If your product breaks when dropped, needs specific orientation, or has irregular shapes, vertical filling won’t work. Horizontal conveyors carry products gently to the forming station and position them before film wraps around them.

The packaging styles your market expects narrow your options.

Vertical systems produce pillow bags and gusseted bags efficiently. Pillow bags have a fin seal down the back and work for commodity products. Gusseted bags have side folds that expand when filled, letting them stand on shelves. These formats suit coffee, snacks, and pet food where you need shelf presence without premium features.

The horizontal FFS bagging machines market has grown significantly due to demand for premium retail packaging. These systems create various formats that drive retail sales, including

If retailers demand these formats or consumers expect resealable packaging, horizontal equipment becomes necessary.

Your building dimensions limit which machine fits.

Vertical equipment occupies minimal floor space because it extends upward. If you’re adding capacity where floor space is tight, vertical machines fit into small areas. You need ceiling height for the tube former and product drop distance, typically 12-15 feet depending on bag size.

Horizontal machines need floor length for the production sequence. The conveyor, film unwinding, forming stations, and sealing equipment arrange in a line that can extend 20-30 feet. That works in facilities with lower ceilings where vertical equipment won’t fit.

Equipment expenses differ between machine types.

Vertical systems cost less upfront and deliver lower ongoing expenses:

Horizontal machines involve higher investment but provide capabilities that can justify the cost. If you sell premium products where packaging drives purchases, the format options through horizontal systems support higher retail prices. The ability to add zippers, spouts, and custom shapes separates your products from competitors using basic pillow bags.

Film properties must work with your equipment’s systems.

Vertica FFS baggingl machines need film stiff enough to form tubes as it wraps around the tube former. The material must seal at high speeds and support product weight during gravity filling. If film is too thin, tubes collapse and create filling problems.

Horizontal machines require film that tracks through dual web paths and seals through multiple layers when forming gussets. The material needs body to form pouches that stand upright after filling.

XIFA Group’s design department provides customized sizes and logo typography designs based on your specific machine model. Our team works with technical engineers to ensure film specifications match your equipment capabilities. We adjust film thickness for proper forming, width dimensions to match capacity, and seal strength parameters for your production speeds.

Contact our technical team to discuss film specifications that match your FFS machine requirements.

Ensure seamless integration with your existing VFFS/HFFS machinery. We provide professional machine-matching tests to eliminate downtime risks.

From high-gloss to premium matte finishes. Our multi-layer co-extrusion and rotogravure printing ensure your brand stands out with industrial-grade durability.

Specially engineered for high-speed automated lines. Our films offer superior puncture resistance and elastic recovery to prevent breakage during fast filling.

Vertical FFS bags use gravity-assisted filling for free-flowing products and feature pillow or gusseted formats. Horizontal FFS bags accommodate solid items or premium formats like stand-up pouches with precise product placement.

Vertical FFS systems have lower initial investment and maintenance costs. Horizontal systems cost more upfront but provide greater format capability for premium packaging.

No, film must match your specific machine’s forming and sealing systems. Thickness, width, and seal patterns need to align with your equipment specifications.