FFS heavy film is the preferred choice for fertilizer packaging because it creates hermetic seals that prevent moisture damage and product degradation. This material delivers better protection than traditional woven bags while supporting faster automated production that cuts long-term operating costs.

Fertilizer manufacturers face specific packaging challenges that standard materials can’t solve well.

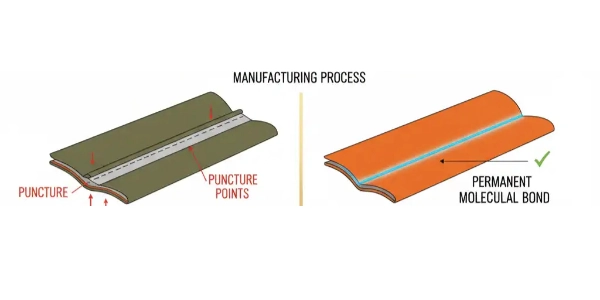

The primary issue is moisture control. Fertilizers are hygroscopic, which means they absorb water from the air. When moisture gets inside packages, fertilizers cake together, lose nutrient value, and become difficult to apply. Traditional woven bags with stitched closures leave needle holes and fabric gaps that let humidity penetrate.

Another challenge is product leakage. Fine granules and powders escape through the gaps in woven fabric and stitch holes, creating workplace contamination, product loss, and weight shortages at delivery. This costs money and frustrates customers.

FFS heavy film solves both problems through its multilayer construction and sealed closure system. The material combines polyethylene or laminated polypropylene layers that block moisture while heat-sealed or ultrasonic-sealed closures create airtight packages with zero gaps.

Here’s how FFS heavy film differs from traditional woven bags when it comes to packaging:

| Feature | FFS Heavy Film | Traditional Woven Bags |

| Sealing Method | Heat/ultrasonic sealed, airtight | Stitched closure with needle holes |

| Moisture Barrier | Multi-layer protection | Poor to moderate, needs liners |

| Leakage Control | Fused seams stop leakage | Prone to leakage through gaps |

| Anti-Counterfeiting | Integrated security, reverse printing | Limited, surface printing only |

| Tamper Evidence | Visible hermetic seals | Can be reopened and re-sewn |

| Production Speed | Automated, 100+ bags/minute | Manual/semi-automated, slower |

| Material Cost | Lower cost roll stock | Higher cost pre-made bags |

FFS heavy film uses fused seams that bond the material together permanently. You can’t pull these seals apart without tearing the film itself. Traditional woven bags rely on stitching, which creates a line of holes running through the closure. Even high-quality stitching can’t stop microscopic air and moisture movement through these perforations.

That sealed construction means FFS packaging bag formats provide better barrier properties without needing separate inner liners. Woven bags need additional PE liners inserted inside to achieve comparable moisture protection, which adds cost and production complexity.

FFS packing bag technology lets manufacturers integrate anti-counterfeiting elements directly into the packaging structure.

High-definition printing sits beneath the film layer where it resists scuffing and abrasion. You can add security features that stay intact throughout the supply chain:

Traditional woven bags use surface printing that wears off during handling. The stitched closures can be cut open and re-sewn without leaving obvious evidence, making counterfeiting and tampering easier.

Fused seams in FFS heavy film create complete containment. Fine powders and small granules can’t escape because there are no gaps in the seal. Traditional woven bags allow minor but constant leakage through stitch holes and the woven fabric structure itself.

This leakage creates several problems. Warehouses accumulate fertilizer dust that needs cleanup. Transport vehicles get contaminated. Customers receive bags that weigh less than the labeled amount. Workers breathe in fine particles during handling.

FFS heavy film handles the demanding environments fertilizer packages encounter during their lifecycle.

The multilayer construction provides the tensile strength needed for bulk fertilizer packaging. Bags hold up during automated high-speed filling, stacking in warehouses, and rough handling during transport without tearing or bursting.

This durability matters when you’re packaging 25 kg or 50 kg bags that get stacked six pallets high. Bag failure at that point creates safety hazards, product loss, and cleanup costs.

Water exposure ruins fertilizer products. FFS heavy film’s barrier properties isolate contents from humidity and liquid contact throughout storage and transport.

The material outperforms traditional woven fabric significantly. Woven bags need inner liners added separately to get comparable moisture protection, and those liners can shift or tear during filling, creating weak spots.

Many fertilizer operations store bagged products outdoors or in open warehouses where packages face direct sun exposure and temperature extremes.

FFS heavy film includes integrated UV stabilizers that prevent sun damage:

This weather resistance extends package life and reduces replacement costs. Traditional woven bags without UV treatment degrade quickly when stored outdoors, becoming brittle and prone to tearing within months.

FFS technology changes how fertilizer packaging lines operate.

The form-fill-seal process uses roll-stock film rather than pre-made bags. These cost less when sourced in bulk and occupy less warehouse space than stacks of empty woven bags. You can store weeks of packaging material in the space that would hold just days of pre-made bags.

Automated systems build packages, fill them, and seal them in one continuous motion. This boosts throughput compared to operations where workers manually load pre-made bags onto filling equipment:

Production lines can switch between different bag sizes by adjusting machine settings rather than swapping out entire inventories of different pre-made bag formats. That flexibility helps when packaging multiple fertilizer products or serving markets with different size preferences.

Finding the right FFS bags manufacturer determines whether you actually get the performance and cost benefits this technology offers.

XIFA Group manufactures FFS heavy film fertilizer packaging bags designed for the demands fertilizer products place on packaging materials. Our products handle the challenging conditions these packages face during storage and long-distance transport.

Our materials provide:

You can customize size, GSM specifications, color, and printing through our in-house design teams. Our quality control includes QR codes for batch traceability, and our 400 million bag annual capacity means stable supply for large-volume operations. We also provide global export support with after-sales service including on-site help when needed.

If you’re comparing fertilizer packaging materials for your operation, our manufacturing and trading structure helps control costs while delivering the performance modern fertilizer distribution needs. Contact us today to discuss FFS heavy film options that match your production requirements.

FAQ

What makes FFS heavy film better than traditional woven bags for fertilizer?

FFS heavy film creates hermetic seals that stop moisture and air from entering packages, includes integrated anti-counterfeiting features, and supports automated high-speed production that traditional stitched woven bags can’t match.

Can FFS heavy film withstand outdoor storage conditions?

Yes, FFS heavy film includes UV stabilizers and temperature resistance that allow outdoor stacking and long-distance transport without the material breaking down or cracking in different weather conditions.

What production speeds can FFS heavy film packaging achieve?

FFS systems run at 100+ bags per minute with automated filling and sealing, which exceeds the speeds you can achieve with manual or semi-automated traditional bag filling operations.