Every industry that involves bulk material loading and transportation has a necessity for bulk bag handling equipment. This could be processed powder, grain, or any dry bulk material. Such operations can either go on smoothly, or cause extensive downtime. This guide will show you exactly how to streamline your bulk bag handling operations and practices, from equipment acquisition to procedures that promote safety and effectiveness during operations.

It is crucial to focus on understanding the particular requirements of an operation and incorporate relevant strategies that aid success in bulk bag management. Because a contemporary bulk bag can carry over 300 times its weight, appropriate handling equipment is not just a matter of good practice, but it gives a good assurance of safety and promoting productivity. Are you new to the bulk bag handling scene or simply want to replace your existing setup with improved ones? This article provides straightforward advice to help you carry out your bulk bag operations.

Bulk bags, also known as Super Sacks or FIBCs, are large, flexible fabric containers that are used for the storage and transportation of dry bulk material. These multipurpose containers are so strong that they can lift as much as 300 times their own weight, allowing them to be used in numerous industries.

Key takeaways:

All business activities rely on seamless bulk bag unloading. Efficient working practices and equipment can:

One of the most important factors that needs to be considered is to have bulk bag handling equipment to maximize effective unloading processes. Here are some items of equipment that are worth looking out for:

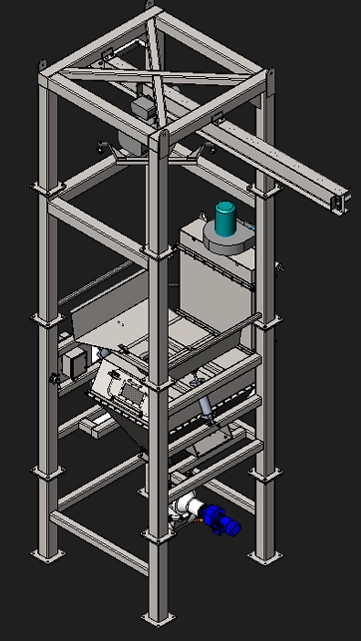

Designed for the rapid emptying of a single super sack or large amounts of bulk material, the bulk bag unloaders can handle more than just one super sack. These systems, meant for heavy-duty applications, are made of either carbon steel or stainless steel and can handle bulk materials such as powders, grains, and granules.

Some of the essential attributes of bulk bag unloaders are:

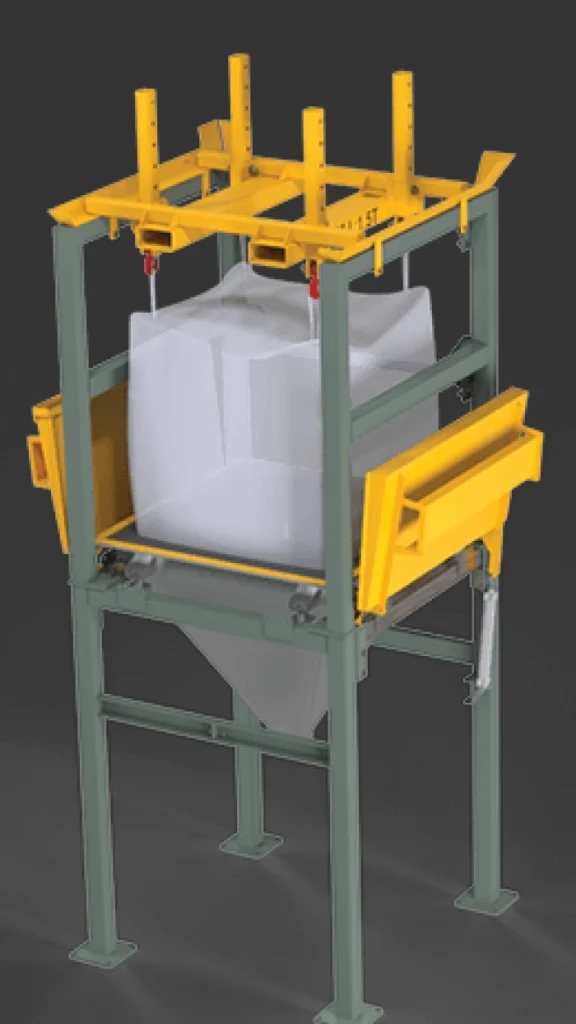

Bulk bag lifting devices, also known as bulk bag lifters, are specifically built to handle and unload FIBCs while ensuring safety and efficiency.

The devices come as standard with:

Controlled discharge of bulk bags into downstream processes or storage containers is performed by the bulk bag dischargers, which are mechanical devices for emptying a particular bulk bag.

They usually consist of:

When removing bulk bags from containers, these procedures and other alternatives should be followed in order to avoid any form of mistake:

Prioritize safety: As a prerequisite, conduct training for all employees and provide them with the necessary Personal Protective Equipment (PPE).

Conduct pre-handling inspections: Find damage, tears, or other operational bulk bag abnormalities prior to removal. Determine the load value and verify that the bag used to contain the substance is acceptable for the bulk material type.

Adhere to load capacity: Logically, it is common sense to be aware of the maximum weight of filled bulk bags and always follow them to avert barrel breakdown and accidents.

Use proper attachment techniques: Notice how the bulk bag has already been fastened to the handling machines before the activity of lowering or moving the bulk bag.

Maintain a clean workspace: It is necessary to ensure that the working environment is kept clean of all moving risks and dirt.

To boost your bulk bag handling processes even further, you may consider the following suggestions:

Implement a systematic approach: It is important to create a standard operating procedure (SOP) for each method of bulk bag unloading so that all operations maintain uniform efficiency.

Use proper storage techniques: Allow bulk bags to be securely stored in such a manner as to allow quick access and minimize the time taken to handle them. It might be sensible to install some racking systems or have mast heads.

Invest in automation: If practical, add automated systems for bulk bag handling so that manual labor is reduced and the amount of work done is greater.

Regular maintenance: Set a periodic maintenance schedule for each type of bulk bag handling device to ensure that there are no sudden device breakages and that all equipment is working in its efficient manner.

Employee training: All relevant staff involved in bulk bag handling should be taught the methods in which bulk bags must be handled properly within a safety procedure.

Despite best practices, challenges can arise during bulk bag unloading. Here are some common issues and solutions:

| Challenge | Solution | |

| Dust Control | The processes involved in unloading can lead to dust, creating various health and safety risks. | Put dust control measures in place, for example enclosed unloading stations or dust collection systems. Alternatives used may include using bulk bags that seal completely to create dust-free closures. |

| Material Flow Issues | A portion of the materials to be unloaded may lag behind and fail to discharge from the bulk bag, giving rise to significant losses and obstructions. | In this regard, bulk bags should be equipped with unloader hoppers that come with either an agitating or vibration system that aids the material flow. For troublesome materials, use special flow aid devices or liner systems to control the material flow. |

| Static Electricity | A hazard is in those materials that may cause static build-up during its handling. | If handling knapsacks that discharge static build up, these include. Use bulk bags of anti-static or conductive materials. Make sure all handling tools are well-grounded. |

Bulk bag handling is more than just the transporting of materials from point A to point B — it is about completing a process efficiently and safely while maximizing productivity and minimizing risks. Improving material handling operations is achievable through proper equipment investment, process implementation, and keeping abreast with the latest developments in the industry.

Furthermore, bulk bag handling should be considered as an activity that focuses on improving processes. The type of materials handled will change the equipment to be used, but there are some universal principles that must be adhered to: safety and efficiency are always paramount. XIFA Group provides numerous bulk bag handling solutions from which you can benefit. For professional assistance, don’t hesitate to contact them.